Tips and tricks from Interpack 2023

VANA has been to #Interpack2023 packaging fair in Düsseldorf: Here is an insight into the tips and trends we have brought home to you:

Sales packaging in focus

The big focus is on sales packaging when thinking it into in a more environmentally friendly direction, and here food gets a lot of focus.

The big question is, if there is a huge easily accessible market waiting if we on focus on secondary (multipack) and tertiary (transport) packaging?

Recyclable film for food

Several packaging manufacturers have developed flexible packaging which is recyclable.

One example is KRAUS FOLIE. They have developed a 5- and 9-layer PE, PP and barrier-oriented film that can be used for so-called mono-material laminates.

This means that the flexible film is recyclable because the used barriers - PE/PP/EOVH - are compatible with the recycling stream for PE/PP (however, please note that there are requirements and criteria for the composite amount - see more in the Plastics Industry design guide here.

At the fair, materials other than the ones we have traditionally used most were also shown e.g.:

Biodegradable service packaging

One example is service packaging made from dried palm leaves, which reportedly requires fewer resources in the washing and drying process. The example below is from the company LEEF, which says that their service packaging is biodegradable as both home and industrial composting. Their goal is clear: "to avoid plastics in service packaging".

However, an observation point in this connection is that the Danish infrastructure for biodegradable packaging is currently not as strong as other material fractions. We therefore recommend researching this part of the process thoroughly if you want to try this type of alternative solution.

Find more information about LEEF here.

Wood fibre packaging in several versions

Another example was a newly developed packaging for e.g., chocolate in pure fibre material instead of the well-known aluminium foil and a blister pack where the usual plastic window has been replaced with a wood-based biopolymer. This means that the packaging in its entirety consists only of wood fibres as raw material.

When sorting and recycling, the cardboard part must be sorted as cardboard waste, and the bioplastic must be sorted as plastic: Bioplastic material does NOT destroy the recycling stream of plastic, if it is degradable. Learn more about it at the Plastics Industry.

New types

You can also be inspired by other things to meet future demands for less packaging (waste).

Below is, for example, a wine packaging with tap, which probably best comes in the category with a bag-in-box wine. But in this type of packaging, the cardboard box has been omitted, and instead the 'inner bag' has been left to make up the entire packaging. This 'saves' an entire type of packaging, and there can also be something to gain on the transport side if several units can be packed in the same space.

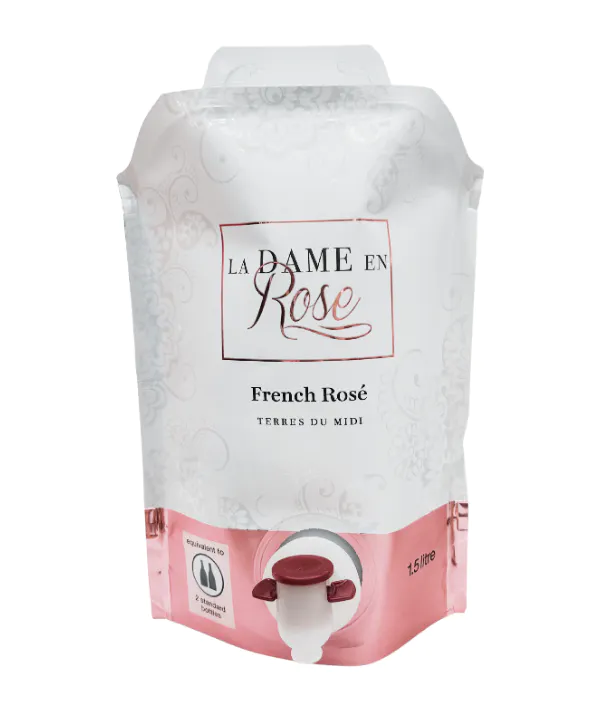

If you want to take it a step further and want to avoid having to “tap your wine”, then there is also this “doypack” packaging (below), which you can imagine could make an excellent packaging for a wine.

With these two examples, we naturally have a potential consumer barrier to accept wine in a plastic packaging, because we do not yet see it unfolded on a large scale on the Danish market.

Another 'new' shape may be to consider the design of the packaging so that the packaging units can be packed more tightly or with volume optimisation in the secondary packaging. Thus, less air and more products are transported.

A comparison of the packaging below can give a sense of how space can be optimised, e.g., by using a square bottle rather than the more traditional round bottle.

The transport packaging

Pallets are well known to work in recycling systems both in wood and in plastic. But here too there are possibilities, e.g., a pallet manufacturer talks about a space-optimised pallet, which means minimised wasted space from the pallet design to the maximum. This means that you can load several pallets onto one load.

In addition, the most well-known transport box, namely the cardboard box, can also be replaced with a reusable packaging, in the form of plastic transport boxes. Many of these boxes are also designed so that they are fully optimised for the dimensions of the pallets, so they 'lock' into each other via their design without the use of, for example, edge strips, film or strips.

Many of the pallet manufacturers also offer logistics service, which is one of the things that can be difficult for a company to manage.